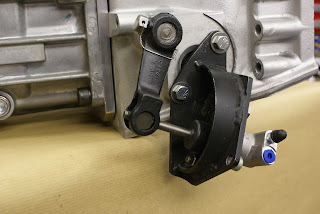

I had every intention of converting the clutch from mechanical to hydraulic operation and to that end purchased a 150 slave cylinder with mounting bracket. The bracket did not exactly fit the 120 bell housing and required a fair bit of fettling to get the push rod moving at something like the correct angles when moving the clutch operating lever. It did eventually all line up reasonably well but looked like a bodge, as if it was never meant to be there.

|

| This just doesn't look right |

So, having acquired a likely master cylinder some time back, I set about looking at how to best utilise it in conjunction with the existing pedal arrangement. With the new slave cylinder fitted, there is no longer a place for the end of the clutch operating shaft. This can possibly be resolved by making up a substantial plate with some form of bearing for the remote end of the cut down shaft. Also, the operating lever will need to be relocated with a new key way machined into the shaft and the chassis will need some holes drilled to attach the plate. It's all getting horribly complicated.

Time to ask the obvious question.

Why exactly do I want to operate the clutch hydraulically?

Whilst the mechanical arrangement has lots of parts, it is in fact reassuringly simple with very little if anything that could fail catastrophically.

|

| As usual with Jaguar design, many parts make up the clutch operating mechanism. Note washer in bottom right hand corner and see "whats that clicking noise" below. |

|

| Very odd ware characteristics on end of clutch shaft, bearing and cup. |

On balance, it's clear that the right and proper thing to do is to restore it to its original mechanical state, rotating happily in new bronze bushes, carefully lapped into their cups and then lubricated with very best grease that money can buy. Why did I ever think it a good scheme to usurp this fine piece of engineering with masters, slaves and their vile corrosive hydraulic fluid. Whilst on a roll so to speak, perhaps I should consider upgrading the braking system with cables, rods and levers!

My good friend Richard Cook who fortunately understands my passion for such things, machines the badly worn end of the shaft and fits a sleeve making it as good as new. Medical science has some catching up to do.

|

| Resplendent with new sleeve, bush and cup. What more could an original clutch operating shaft want? |

So I guess the only remaining question is :

Is there anyone out there who would like to buy a brand new Tilton 74-700 7/10" Master cylinder kit complete with remote mounting kit, hoses and clips and an XK150 slave cylinder with slightly butchered mounting bracket.

|

| Mr Happy Shaft back home and back in employment. |

|

| Tilton Master Cylinder - Heading for EBay |

Whats that clicking noise?

Pushing the clutch pedal on my 140 would often but not always produce a light clicking noise which could be felt through the pedal. As it came and went, I was never too concerned. Last winter I decided to investigate and removed the whole clutch shaft assembly, cleaned it, replaced the bearings, "O" rings etc. and re-assembled it. The result was a satisfying silence. The noise had gone, for about a week, then it re-appeared. With assistance and a listening tube, I established that the noise emanated from inside the chassis. The end of the spring had worn and worked its way into the chassis side, sometimes catching and winding up then twanging free with the shaft motion. It seemed strange that nothing was fitted to the shaft to stop this happening. About this time I bought Bernard Viarts amazing book - Jaguar XK140 Explored.

|

| Bernard Viarts amazing book on the 140 and a typical drawing. A 120 edition is hopefully due out later this year |

The superb drawing of the clutch shaft assembly, although for a left hand drive car, shows a washer (C3295) between the spring and the chassis. Definitely not present on my car and very unhelpfully not shown on plate F of my Jaguar parts manual. I found a suitable washer and did a trial fit. Removing the shaft to fit the woodruff keys, the washer fell off the end and into the chassis. My 'magnet on a stick' fished around inside the chassis and was carefully removed with not one, but two washers attached! It doesn't matter which way you remove the shaft, the washer will most likely fall off into the chassis. Consequently, you would never know it was ever there, and the parts manual nicely confirms its non existence.

Prop Shaft angle

The new prop shaft to fit the T5 box finally arrived and was fitted, but the angles required by the UJ's to meet the diff seemed a bit severe. The reason of course was that the re-tempered springs are sitting high with very little weight to settle them. I calculate that a full fuel tank, rear part of the body with boot contents and the best part of two passengers would approximate to 200Kg's.

Fortunately I have to hand a pallet of coaxial cable with each 250 Mtr reel weighing about 11Kg. Stacking 18 reels over the axle settles the springs very nicely and makes the prop shaft angles acceptable.

|

| 18 reels of coaxial cable approximately equates to the back half of the body, a full tank of fuel and a couple of big lads. Springs and prop shaft angle now look about right |

Cylinder Head and Gasket - Final solution

Following on from my previous post and the problem of fitting the camshaft sprockets, assuming my calculations are correct, it looks like I will have to settle for a thinner gasket and a compression ratio of 9:1. Rob Beere supplied another Cometic composite gasket, this time 60 thou, and it all goes back together without a hitch.

|

| Sprockets fit easily to cams with gasket reduced to 60 thou. Why has the head got this odd double stamped engine number? See post 10 for the most probable explanation. |

|

| Could valve seat depth and profile be responsible to reduced chamber volume? |

Miscellany - related topics

Beamish Rally

A couple of weeks after this wonderful day out, I received a phone call from Mr George Jolly, the event organiser to tell me I came first out of around 150 entrants. Totally unaccustomed to winning anything ever, this came as very nice surprise. However, the actual credit for the win must go to navigator Tony Firth, who has an encyclopedic knowledge and recall of all things relating to old motors, no doubt giving us a super high score for the quiz part of the rally.

Stuffed again by the weather men.

The biggest classic car event in North East England at Newby Hall near Ripon was cancelled after a "pitch inspection" four days prior to the event. No doubt the forecast of a further twenty odd hours of heavy rain over the next three days would have played some part in the decision. Apart from the occasional light shower on Friday, the forecast was around 95% wrong.

Next Post beginning of August